What is air shower?

The cleanroom has strict requirements in the flow channel and the logistics channel, that is, the entry and exit of people and things must follow the regulations. The air shower, also known as the air shower room, is the necessary tunnel for personnel to enter and exit the cleanroom. When the person passes through the air shower room, the dust on the cleanroom work cloths overalls is blown off by the high-speed clean air flow to prevent the dust from entering the clean room. The chamber also serves as a buffer for the airtight chamber to seal the clean room and is an essential equipment in the design of the cleanroom.

Cleanroom Project Cross-section Diagram

The area marked with the blue part in the figure is an example of the use of the air shower in the cleanroom. It acts as a barrier buffer for the clean and sub-clean areas to block dust from entering the high cleanliness area.

Classification of air shower

Air shower room can be divided into the following types: single blow air shower room, single double shower room, single three air shower room, double shower room, three double shower room, air shower channel, stainless steel wind Shower room, intelligent voice air shower room, automatic induction sliding door air shower room, L-shaped corner air shower room, uninterrupted air shower room, rolling door air shower room, cargo air shower room, explosion-proof air shower room, anti-static air shower room, etc.

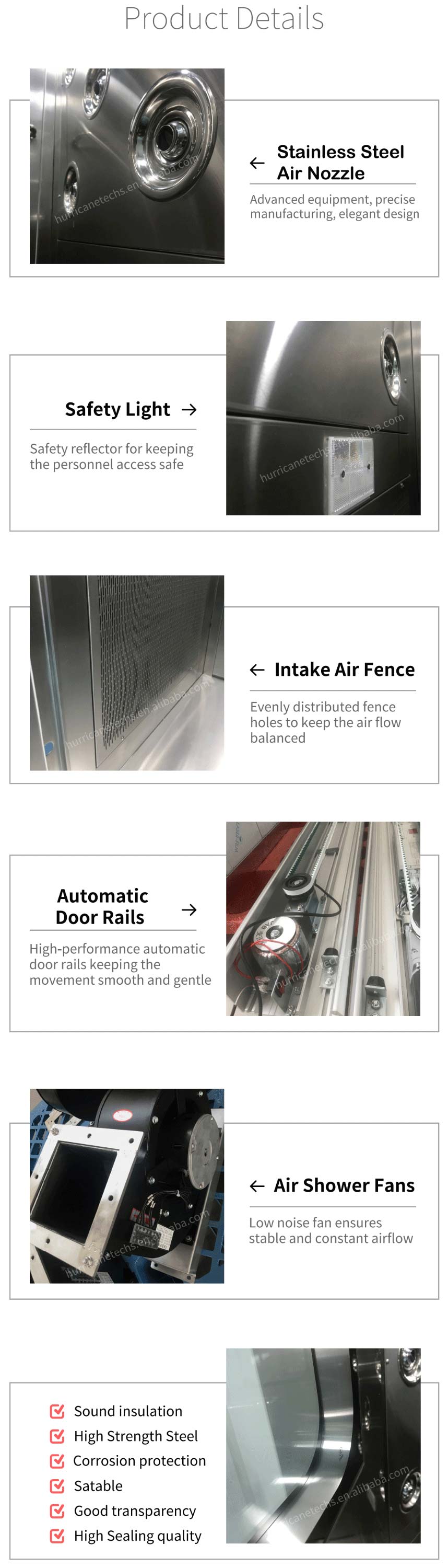

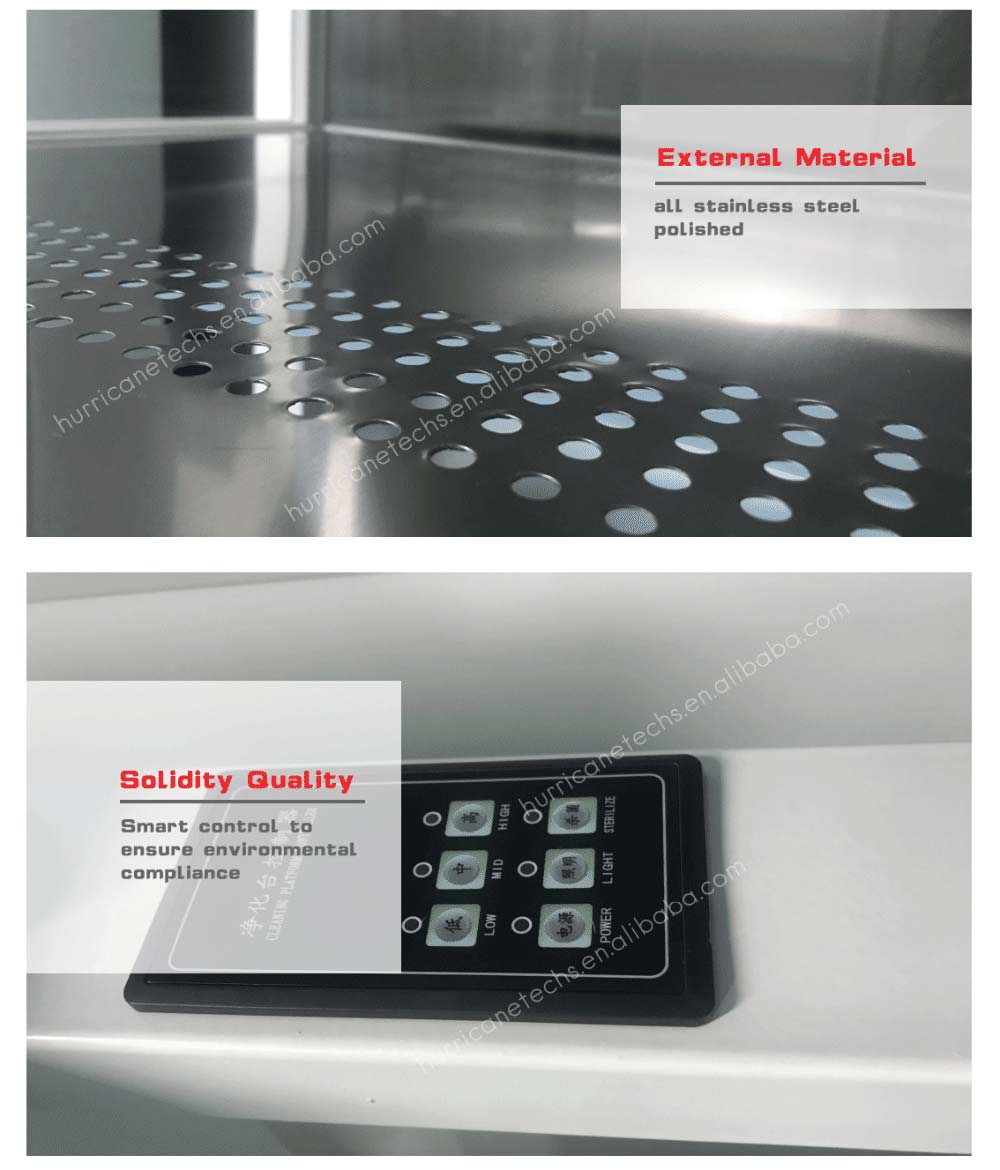

Main Features

1. The system use automatical controls unit for the operation, the double door uses electronic interlock and has a photoelectric sensorWarehouse Show

Founded in August 2003, Wuxi Hurricane Purification Technology Equipment Co., Ltd- is located at Wuxi Yanqiao Industrial Park and belongs to the private sole proprietorship. Hurricane Purification Technology Equipment company is engaged in design, production, installation, and testing of class 100-level to class 300000-level cleanliness cleanroom purifying engineering in medicine, food, electronics, biochemical industry, and other industries; the company is also engaged in processing and manufacturing high-efficient filter, cleanroom workbench for single and double persons, air shower(room), class 100-level laminar hood, pass through chamber/box, cleanroom color plate and other cleanroom equipment for over ten years.

At present, the Company has over 120 staffs, and owns construction and installation certificate of air purifying engineering, safety construction qualification certificate, project manager qualification certificate, and also passes through the ISO9001 quality system certificate.

What is a cleanroom workbench?

Cleanroom workbench is an air purification equipment that provides a local dust-free and sterile working environment. It can control the discharged air in the work area through a special filter channel to prevent emissions to people and the environment. It is a safe microbial-specific clean bench. It can also be widely used in biological laboratories, medical and health, biopharmaceutical and other related industries to improve process conditions, protect operators' health, improve product quality and yield.

Cleanroom Project Cross-section Diagram

The area marked with the blue part in the figure is an example of the use of the workbench in the cleanroom.

How dose the workbench work?

The clean environment is formed in a specific space where clean air (entering air) flows in a set direction. Divided by the direction of the airflow, the existing ultra-clean workbench can be divided into vertical, from the inside to the outside and from the side. The clean air supplied by the air supply filter plate descends through the operation area at a specific speed, is separated in the middle of the operation area, is sucked away by the front air suction hole and the rear suction window, and the air sucked in the front and rear portions of the lower portion of the operation area is mixed. Together, and pumped into the rear positive pressure zone by a blower, in the upper part of the machine, 30% of the air is exhausted from the top through the exhaust filter plate, and approximately 70% of the air is re-entered into the operating zone through the oxygen supply filter plate. To supplement the air discharged from the exhaust port, the same volume of air is replenished from the room air through the operating port. This air will never enter the operating area, just forming an air barrier.

Founded in August 2003, Wuxi Hurricane Purification Technology Equipment Co., Ltd- is located at Wuxi Yanqiao Industrial Park and belongs to the private sole proprietorship. Hurricane Purification Technology Equipment company is engaged in design, production, installation, and testing of class 100-level to class 300000-level cleanliness cleanroom purifying engineering in medicine, food, electronics, biochemical industry, and other industries; the company is also engaged in processing and manufacturing high-efficient filter, cleanroom workbench for single and double persons, air shower(room), class 100-level laminar hood, pass through chamber/box, cleanroom color plate and other cleanroom equipment for over ten years.

At present, the Company has over 120 staffs, and owns construction and installation certificate of air purifying engineering, safety construction qualification certificate, project manager qualification certificate, and also passes through the ISO9001 quality system certificate.