Some seemingly unimportant details in the design and construction of the clean workshop in the electronics factory have greatly affected the purification efficiency and cleanliness of the clean workshop in the electronics factory. In fact, these points of attention are not only applicable to the clean workshop of electronics factory, but also applicable to the clean workshop of other industries. What are the key points in designing and building a clean shop in an electronics plant? With He Jie technology electronic engineering company to understand it!

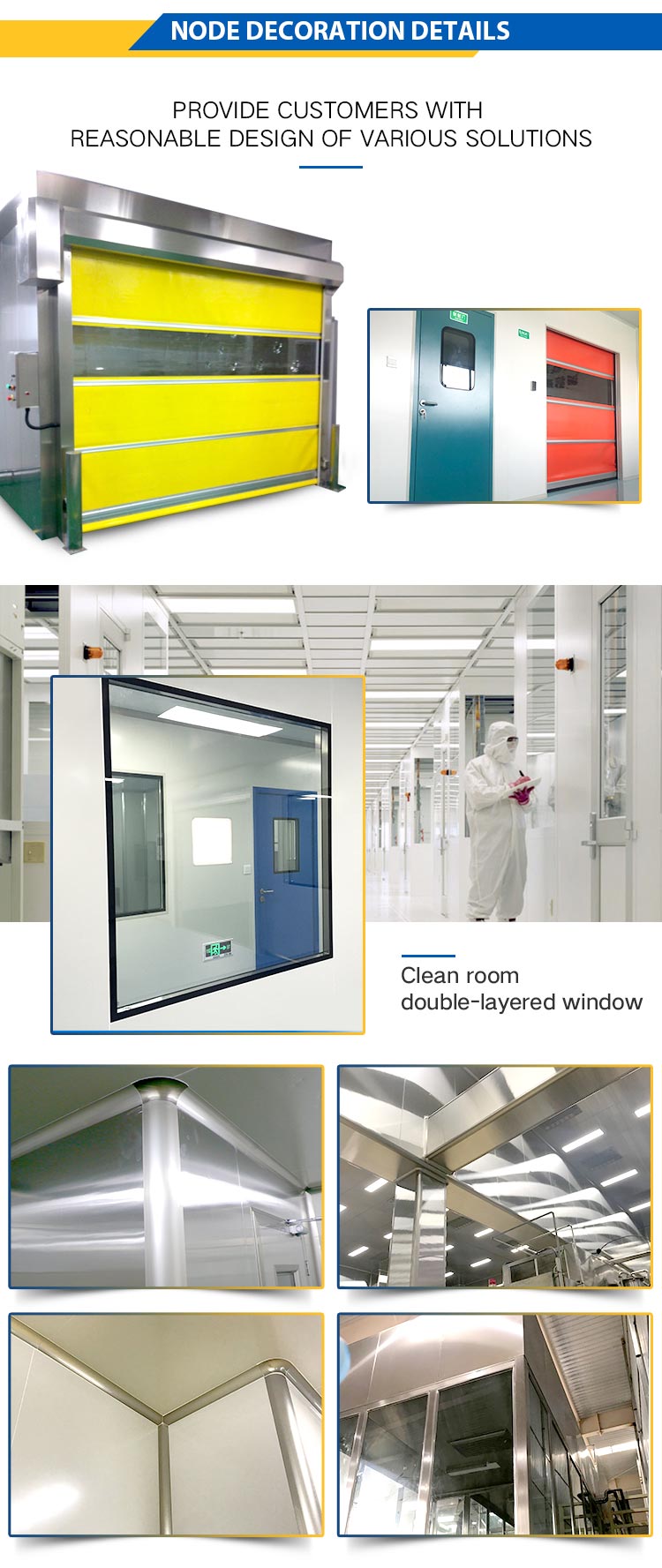

The first is to choose colored steel plates for the partitions, roofs and walls of the clean workshop in the electronics factory. Usually, the thickness of 50mm filled color steel plate is more appropriate, not only beautiful and strong. When choosing floor materials, general electronics workshops use more epoxy resin or PVC flooring. In the selection of efficient air supply port, generally in the high purity chamber, you can choose the liquid tank air supply port, in the punching screen can choose aluminum plate, so it is not easy to accumulate dust, not easy to rust, more clean.

Secondly, attention should be paid to the personnel cleaning of the electronic factory clean workshop. The air shower shall be installed at the entrance to the clean room. The single air shower shall be set up by a larger number of 30 persons. The entry and exit of the air shower shall not be simultaneous. When opened, interlock control measures should be selected. If it is the entrance and exit of equipment and materials in the clean workshop of the electronics factory, it should be set up independently, and the shower room for goods should also be set up. If the transfer of materials or products needs to take place in a different level of clean workshop, a transfer window should be established.

For static pressure difference and purification parameters between different clean workshops, the static pressure difference between different levels of clean workshops should be greater than or equal to 5Pa, and the static pressure difference between clean and unclean areas also needs to be larger. Compared with 5Pa, the air exchange rate of clean workshop depends on the level of clean room. Different levels of clean workshop have different air exchange times. The higher the cleanliness, the more frequent the air change per hour.