Pharmaceutical factory clean room how to do

Overview of clean room

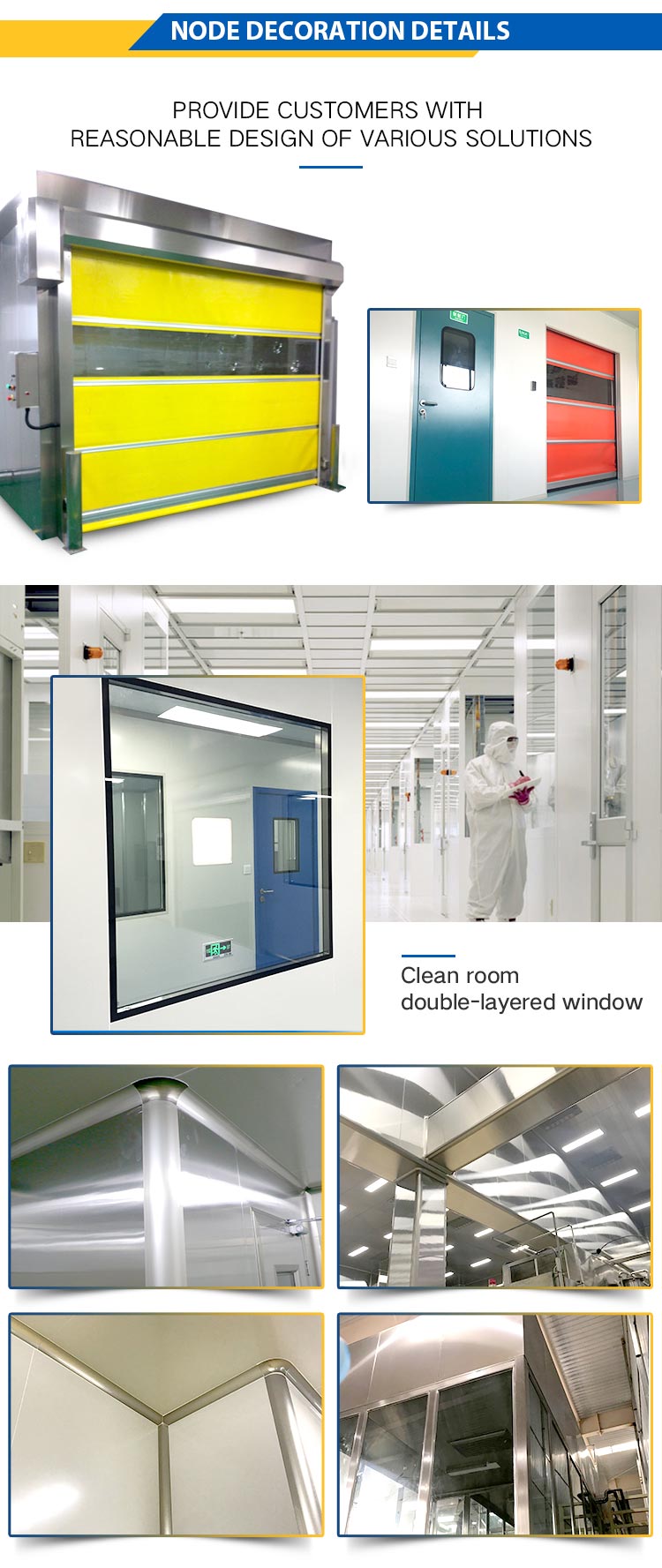

1, the inner surface of the clean area (wall, ground, ceiling) should be smooth, no cracks, tight interface, no particles falling off, to avoid dust, easy to effectively clean, when necessary, should be disinfected. Piping, lighting, tuyere and other utilities shall be designed and installed to avoid areas that are difficult to clean and shall be maintained as far as possible outside the production area.

2, the lamps are clean, embedded and meet the requirements of luminous flux. Explosion-proof lamps with special requirements can be open-mounted, but must be easy to clean, dust free type.

3. The floor of the clean room is made of epoxy self-leveling, epoxy colored sand or PVC base material. It can also be adjusted according to the actual situation.

4, all through the wall, ceiling, ground pipe should be sealed, the window adopts aluminum frame and tempered glass, clean room furniture adopts 304 stainless steel.

Two, clean room design management

1, clean room design to meet the specific production specifications and actual installation requirements of clean roof wall panel.

2, clean equipment clean Windows, clean doors, furniture, fire hydrant box, access control panel, switch socket, power distribution box, etc., need to integrate the professional information to arrange the wall to prevent collision, affect the installation.

3, clean materials and related internal roof keel and other internal strengthening, clean room ceiling technology sandwich due to the need for maintenance can usually be used on the ceiling, clean materials have a system of fire resistance limit.

Three, clean room construction quality control

1, clean room construction scheme, clean room safety scheme, clean room quality plan, control scheme above the ceiling, clean room finished product protection plan, clean area control scheme, construction schedule and some quality system check list need to be approved.

2. Construction disclosure of the project, including construction safety and construction technical requirements, shall be delivered by the contractor's project manager, attended by the supervisor, and signed by the owner's quality personnel.

3. Clean room decoration should ensure that it is not exposed to wind and rain.

4. Clean the roof to a certain area, but it has not been connected with the outer wall. At this time, the adjacent side needs to pull two layers of steel wire protection and hang green nets and warning signs everywhere.

5. Clean rooms usually include the installation of circular arc angles, clean doors, transfer Windows, Windows, embedded panels and other clean rooms.

6, the construction process must consider the transportation of clean room process equipment, should timely communicate with the process engineer to coordinate the order, in order to avoid unnecessary roof, wall panel removal.