The production of electronic chips has very high requirements for the environment, and a good production environment is needed, otherwise it will cause damage to the chip and bring economic losses to the enterprise. Today to tell you about the electronic chip clean workshop construction requirements!

To what extent do electronic chips require a demanding production environment? Its production environment must be sterile, dust-free, static-free, and the humidity in the workshop is also appropriate. Only such a workshop can prevent the chip from being burned and scrapped, in order to effectively ensure the quality of the product and improve the production efficiency of the enterprise. Due to the requirements of the characteristics of electronic chip production process, the construction of electronic chip clean workshop is also put forward more strict requirements.

Because the electronic chip is more sensitive to static electricity, it is necessary to choose anti-static materials during construction, such as selecting anti-static partition materials and selecting anti-static ground materials. In addition, it can also reduce the accumulation and generation of static electricity by controlling the humidity in the workshop. There is also a reasonable construction measures, the electrostatic conductance generated in the workshop to the outside of the workshop. Through a variety of construction measures to achieve the requirements of no static electricity.

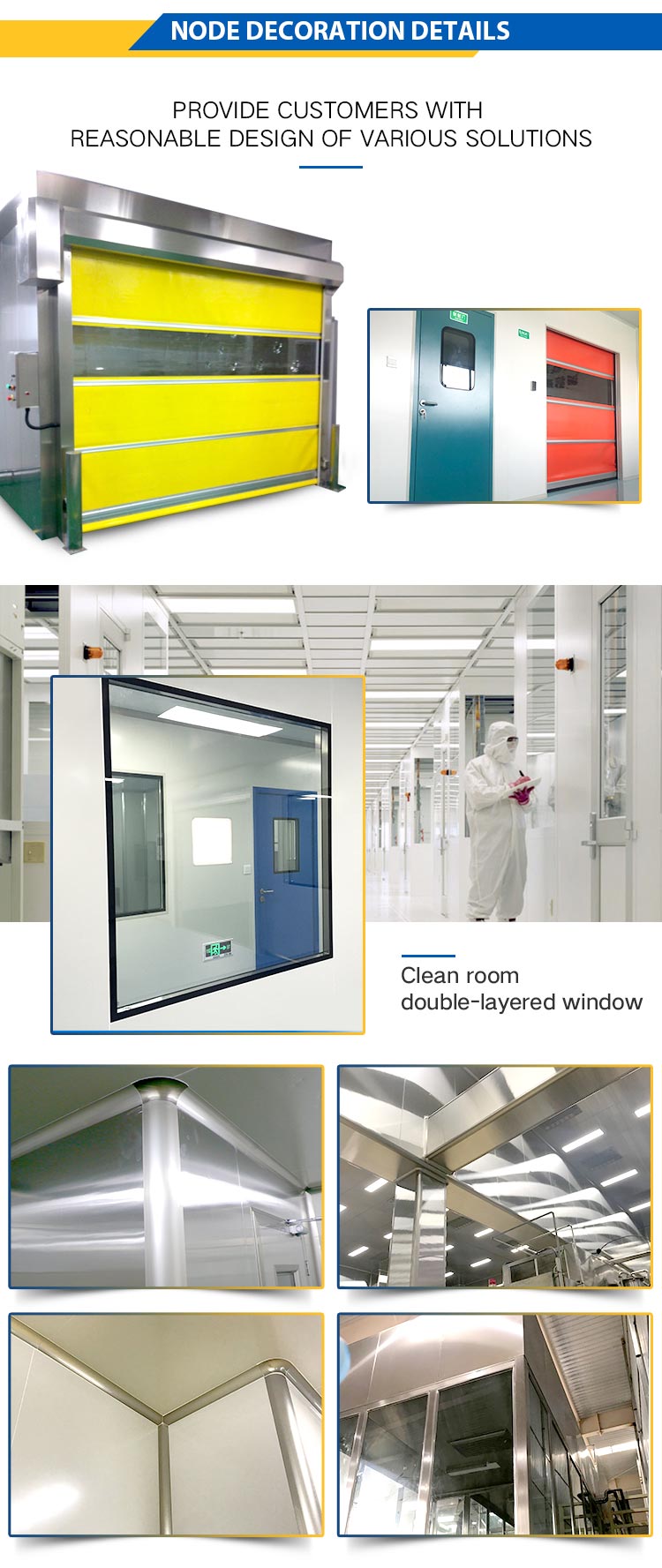

Select the appropriate purification equipment during construction to achieve the requirements of dust-free and sterile. Purification equipment generally has clean air conditioning, junior high school high efficiency filters, FFU, etc., choose what kind of purification measures need to be selected according to the requirements of cleanliness, generally if the chip workshop cleanliness level reached 100, it needs to be covered with FFU, and lay elevated floors. In addition, during the construction, we must pay attention to the air tightness requirements of the workshop, such as the joints of the equipment installation, the joints of doors and Windows, etc., should be sealed using seals to prevent unclean air from coming in from the place where the seal is not good, affecting the cleanliness of the workshop. In addition, when the construction should pay attention to avoid dead corners, the lamp line lamp is best arranged in the technical sandwich, so as to avoid the accumulation of dust.

Construction not only tests the technology of construction personnel, but also tests the quality of construction personnel, construction must be careful, serious, not careless, so as to build a standard electronic chip dust-free workshop.

Due to the space problem, only for reference, I hope to help you, the specific detailed program can visit our website for further understanding, we will continue to explain the clean engineering construction process for you, introduce the requirements of clean engineering and interpret all kinds of electronic clean workshop standards.