The production of electronic products has very high requirements for the environment. It needs to have a good production environment. Otherwise, it will cause damage to electronic chips and bring economic losses to enterprises. This Xiaobian to tell you about it!

To what extent do electronic chips require a demanding production environment? Its production environment must be sterile, dust-free, static-free, and the humidity in the workshop is appropriate. Only such a workshop can prevent chips from being burned and scrapped, to effectively ensure the quality of products, improve the production efficiency of enterprises. Due to the requirements of the characteristics of electronic chip production process, the construction of electronic chip dust-free workshop is also put forward more strict requirements.

Because electronic chips are sensitive to static electricity, it is necessary to choose anti-static materials during construction, such as anti-static partition materials and anti-static ground materials. In addition, it can reduce electrostatic accumulation and production by controlling the humidity in the workshop. There is also through reasonable construction measures, the electrostatic conductivity generated in the workshop to the outside of the workshop. Through a variety of construction measures to achieve the requirements of no static electricity.

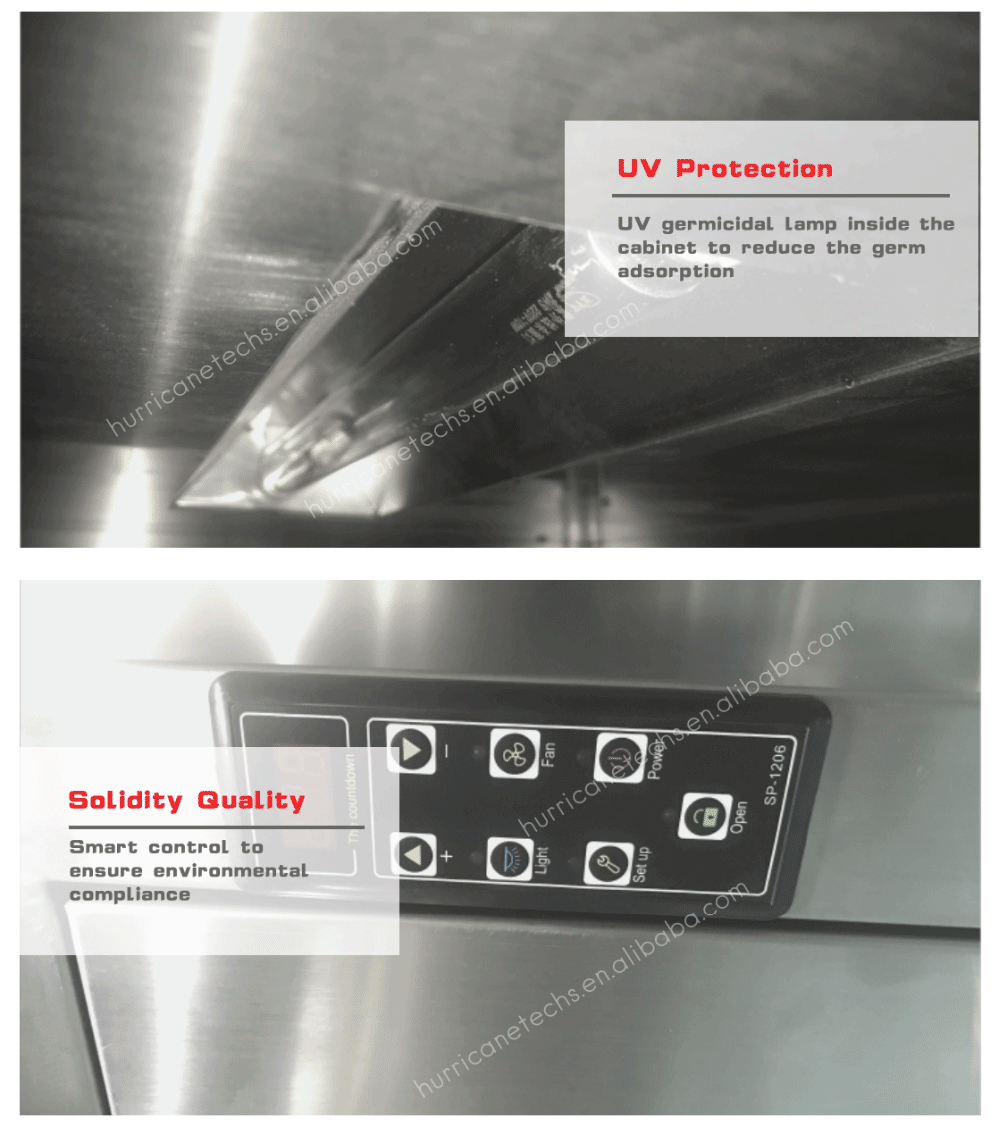

Choose the right purification equipment during construction to achieve the requirements of dust-free and aseptic. Purification equipment generally has clean air conditioning, junior high school high efficiency filter, FFU, etc., choose what kind of purification measures need to be selected according to the requirements of cleanliness, generally if the chip workshop and other cleanliness level reached a hundred, it needs to be covered with FFU, and laid elevated floor. In addition, during the construction, we must pay attention to the air tightness requirements of the workshop. For example, the joints of equipment installation, the joints of doors and Windows should be sealed with sealing strips to prevent unclean air from coming in from the bad sealing place and affecting the cleanliness of the workshop. In addition, when the construction should pay attention to avoid dead corners, lamp line lamp is best arranged in the technical sandwich, so as to avoid the accumulation of dust.

Next Xiaobian to explain to you the construction of electronic chip purification workshop need to follow what steps:

1. Determine workshop planning and design scheme, including workshop area, layout, equipment placement, ventilation system, purification level, etc.

2. Carry out civil construction, including the construction of the ground, walls, ceiling, doors and Windows and other building structures.

3. Install ventilation system and purification equipment, including air purifier, filter, fan, air supply pipe, etc.

4. Install electrical equipment and lighting system, including wires, sockets, switches, lamps, etc.

5, the ground and wall painting and decoration, including the ground paint, wall paint, floor tile, wall tile, etc.

6. Install doors, Windows and partitions, including doors, Windows, partitions, etc.

7, equipment debugging and acceptance, to ensure that the workshop ventilation and purification effect meet the requirements.

8. Clean and disinfect the workshop to ensure the sanitation of the workshop environment.

9. Set workshop signs and safety warning signs to ensure workshop safety.

10. Conducted workshop training and management to ensure workshop operation standards and staff safety awareness.