The production of the electronics industry needs to be in a clean space, so it is necessary to build a dust-free workshop of the electronics factory. What matters should we pay attention to when decorating? Today, Xiaobian will share the decoration scheme of the dust-free workshop of the electronics factory, hoping to help you!

Usually, before the construction of a dust-free workshop, we should first make a good plan, and then discuss and modify the plan for many times to finally determine it. The construction is carried out according to the pre-designed plan, so that every step is feasible and feasible, and it is not easy to make any mistakes. It is a prerequisite for the smooth construction. Each purification engineering company will summarize a set of its own design and construction scheme based on its understanding of the product and years of construction experience. A good scheme can help the purification project to proceed better, while a bad scheme will bring negative effects, slow down the project progress, or even give up the project.

1. Environmental control

The environment control of dust-free workshop of electronics factory is also very critical. Environment control includes temperature, humidity, and static electricity. Temperature and humidity control can avoid material deformation and affect production efficiency. Static control can avoid the problem of static electricity, so as to ensure the quality and efficiency of production.

2. Material selection

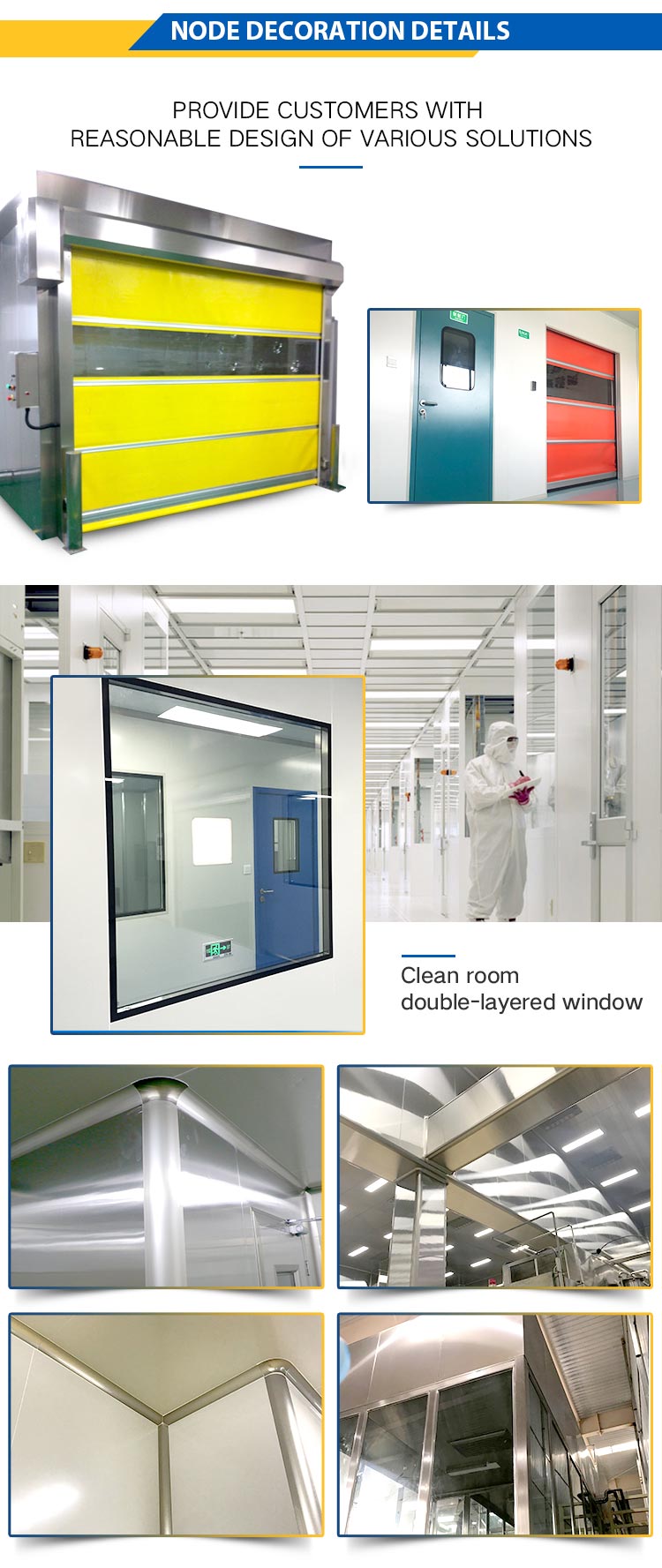

The selection of materials in the dust-free workshop of electronics factory is also very important. The materials must be antistatic, dust-proof, and easy to clean. Generally speaking, the walls and ground of the dust-free workshop are made of stainless steel plate, aluminum plate, polyurethane plate and other materials, and the ceiling is made of aluminum alloy grid plate or mineral wool board.

3. Design of air purification system

Air purification is the key to the dust-free workshop of electronics factory. Therefore, in the design of dust-free workshop, we must take into account the design of air purification system. Air purification system includes air filter, air supply system, exhaust system, air treatment equipment, etc. In the design, according to the needs of the workshop and purification requirements, choose the appropriate air filter and treatment equipment, to ensure that the air quality of the workshop meets the requirements.

4. Air flow design

The air flow design of dust-free workshop in electronics factory is also very important. Reasonable air flow can make the airflow in the workshop smooth, prevent the accumulation of pollutants. Generally speaking, the air flow in the dust-free workshop should flow from the clean area to the polluted area to ensure the air quality in the workshop.

5. Personnel behavior

The purification effect of dust-free workshop of electronics factory not only depends on the design and construction, but also related to the behavior of personnel. In the dust-free workshop, personnel should wear appropriate work clothes and shoes to avoid bringing in pollutants. At the same time, the personnel should abide by the regulations of the dust-free workshop, do not enter and leave the workshop at will, do not eat in the workshop, etc.

To sum up, the design and construction of dust-free workshop of electronics factory need to consider the design of air purification system, material selection, air flow design, environmental control and personnel behavior. Only in these aspects are done well, in order to ensure the purification effect and production efficiency of the dust-free workshop.