Everything is difficult at the beginning. A good design scheme is the beginning of clean engineering. The good and bad of the architectural engineering design level will concern all the engineering construction after the project, and also determine the reliability, stability and rationality of the purification project in the later period. Take a look at the four priorities of electronic clean engineering, so that we have a more in-depth understanding of the purification work.

1. Effective layout of production processes and engineering building plans

Layout process steps as short as possible, reduce cross-type reciprocation, abortion, freight logistics towards effective. To configure the staff clean workshop, raw material purification workshop, in addition to the configuration of the user specified in the commodity process, should also be configured with sanitary ware room, laundry room, storage room, each room independent distribution, the total area of the purification project should be in ensure that the basic provisions of the premise, consistent with the scale of manufacturing operations.

2. Select the building structure and raw materials considering the characteristics of clean workshop

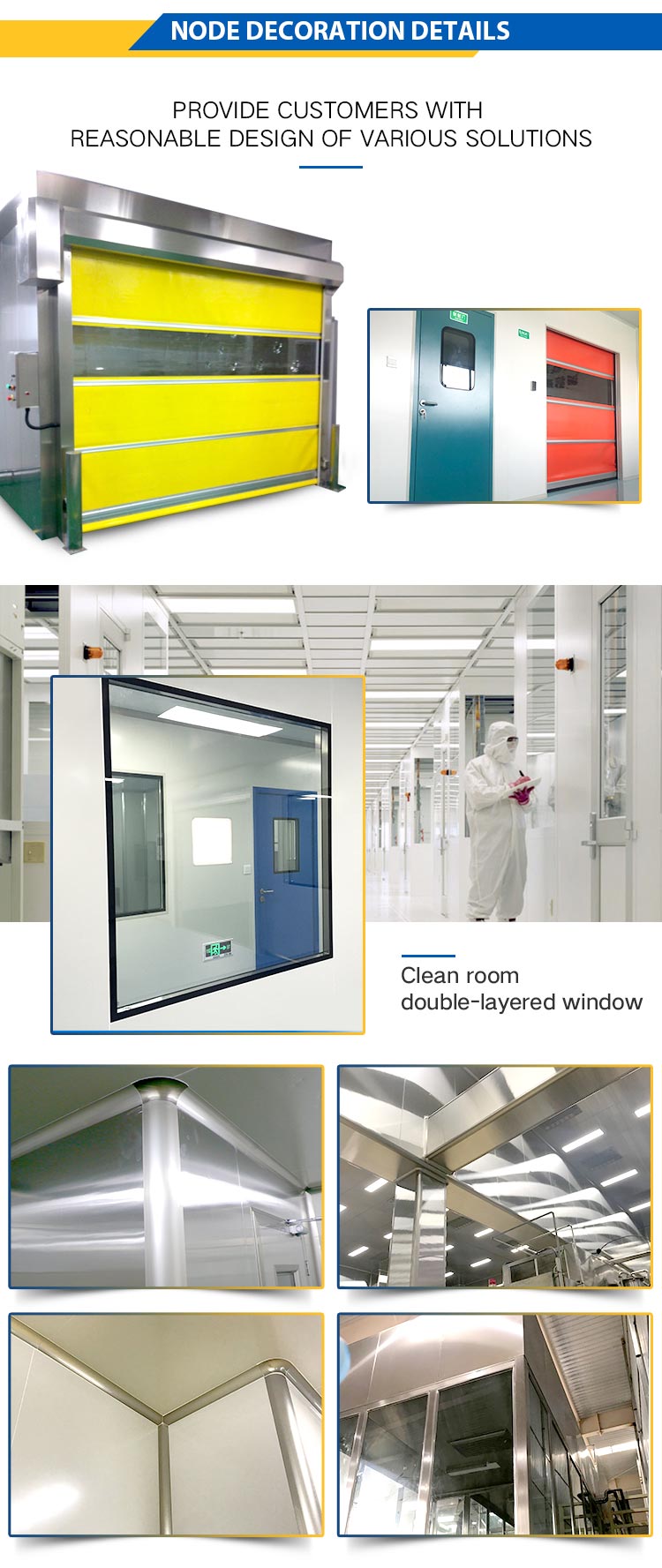

In the design scheme of clean engineering, the wall and roof of the project generally use 50mm thick sandwich color steel plate, which is beautiful and generous and has strong stiffness. Curved wall feet, doors, Windows and other general use of special air aluminum oxide profiles. The road can choose epoxy resin automatic discharge flat epoxy floor or advanced wear resistant plastic floor. If there are antistatic provisions, antistatic type should be used. The return air pipe is generally made of galvanized sheet, which is not suitable for glass fiber cotton raw materials. The lighting lamps should be clean workshop special lighting lamps.

3. Division and layout of air purification system and ventilation system, selection of effective air filtration ventilation and cooling equipment

The standard of the purification equipment mechanism in the design scheme is that the high efficiency of the adjacent secondary filtration device can not be too close, nor can it be too different. General selection of primary effect, medium effect, sub-high efficiency (or high efficiency) three filtration devices. It is also divided into four levels to enhance a high efficiency air supply port. Ventilation system has general ventilation system, organic exhaust gas ventilation system, acid and alkaline vapor body ventilation system, partial alkali vapor body ventilation system, etc. When designing clean workshop, it should be selected according to the specific situation.

4. When designing the clean project, whether it is under construction or the clean workshop that is renewed and rebuilt, it must be carried out in accordance with the relevant specifications and standards.

The prevalence of clean engineering technology was a matter of the 20th century, but today it is known that clean technology plays a key role. With the development trend of goods towards high, fine and sharp orientation, the dependence on clean workshop is also increasing. With the development trend of clean technology, the technology content of clean workshop of basic construction is also increasingly high, and cross-professional personnel can not. In addition to the manufacturing industry, clean engineering technology will be slowly used in the home and public places, for everyone to show a cleaner home life.