Matters needing attention in dust-free workshop design scheme:

1. The design content of dust-free workshop includes reasonable layout process and building plane; 2. Choose the building structure and materials that meet the characteristics of dust-free workshop; 3. Dust-free workshop design should be based on the local energy supply background, reliable and economic cold and heat sources selected; 4. Divide and arrange air conditioning purification and exhaust systems; 5. Choose reasonable air purification and ventilation equipment.

Whether new or rebuilt dust-free workshop, must be in accordance with the relevant national standards, specifications. Five characteristics should be considered in the design of dust-free workshop:

(1) Durability: Dust-free workshop should have durable materials in accordance with the environment, cleaning solution and vibration, equipment and air filtration system in the dust-free workshop. Durability, meanwhile, depends on the dust-free workshop class to build. Semiconductors tend to choose aluminum based on its durability, however, it is not a cheap substance.

(2) Cleaning: In pharmaceutical and bioengineering industries, the walls of dust-free workshops need to be easily cleaned and wiped until they are resistant to viral or bacterial contamination. In the market, cleaning is truly one of the most important enterprises.

(3) Adaptability: Some vendors believe that adaptability can save a lot of money, and adaptability means that the system can be moved or changed at will without incurs great losses. The ability of the owner and the designer is key to change, so they never finalize the original design.

(4) Maintainability: for dust-free workshops, the more strict requirements are the floor, ceiling and wall parts. As for the problem of maintenance, the selection of materials for easy cleaning and maintenance should be given priority. In application of force, ceiling, floor and wall of the three most important to the ceiling, which includes a HEPA and ULPA filter, it can filter out particles of the room, and it often due to the need of each different, its to separate, supply various different parts of the small room, the ceiling is a highly complex system it must be strictly to filter particles, so its design must be accurate.

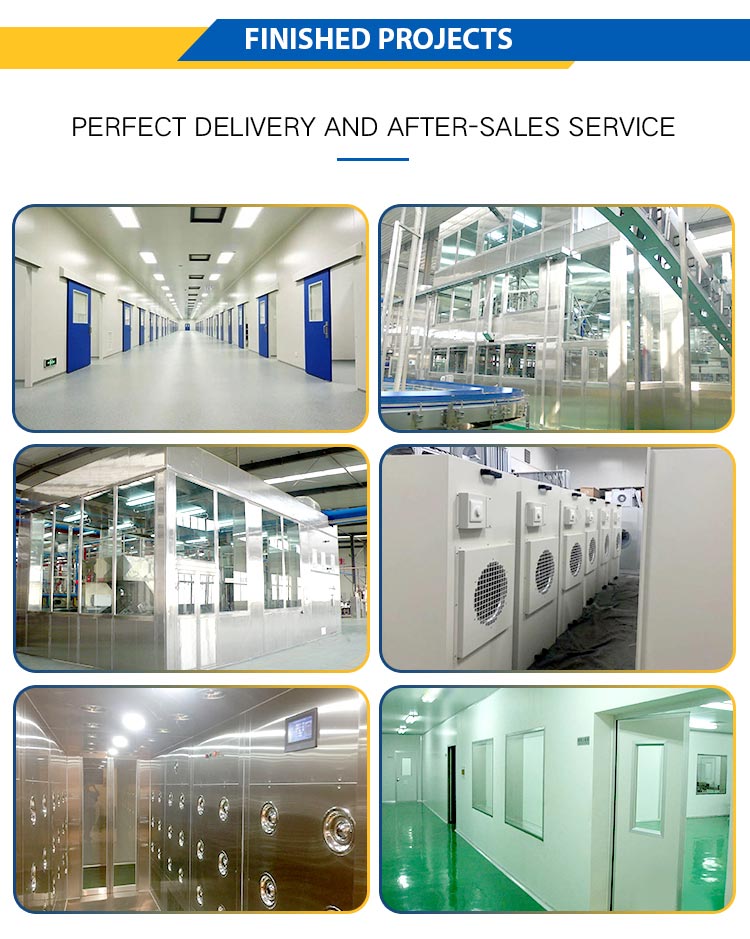

Considering the construction of factory is a comprehensive, professional numerous (cooling, heating, water, air pressure, vacuum, air conditioning, process cooling water, nitrogen, oxygen, fire control, variable power distribution, automatic control, communications, purification decoration, etc.), various professional cannot be fragmented, must be coordinated, recommended way of EPC general contracting for construction. Therefore, the professional purification engineering company China Construction South design team will provide the whole plant planning and design of clean room and supporting system according to the actual situation of the industry, process requirements and management needs of the customer, according to the requirements of energy conservation and environmental protection, and then budget the overall cost of clean workshop according to the planning.